| C6owners :: Forums :: C6 Support :: The Garage |

<< Previous thread | Next thread >>

|

3.0 hdi suspension road noise at speed as the miles go by. |

Please Register to enjoy additional Member Benefits |

| Author | Post | ||

speedfix

|

|

||

Member No: #1043

Location: south west |

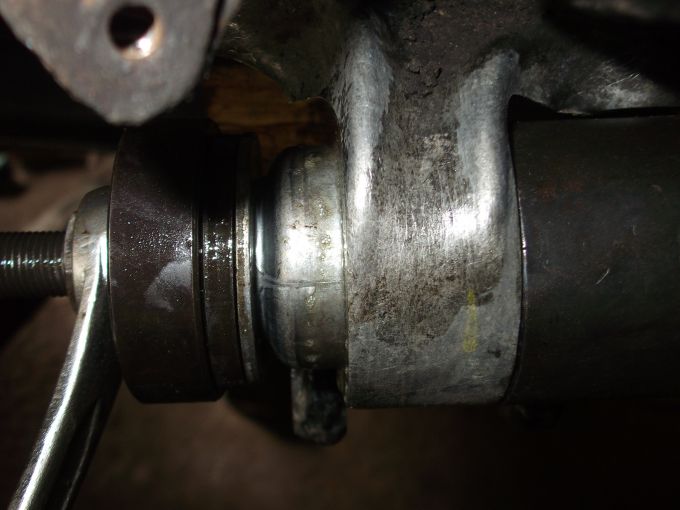

After fitting the shocks in January the ride was greatly improved, however Mot time [three months later] some very slight movement was noted with the FRIP joints. Replaced both and noted that both had the lip seal with no sign of water ingress. IMO with this type it is a total waste of time to fit greasers. IMO the cause is the rollers hammering the sleeve that is not up to the job.Photo showing concave sleeve.  This was not the end of the job but the beginning as the tight new frip joints fitted it seems give rise to showing up other failings. I had more road noise and slight tap rattle on slight rough roads. Could not detect any movement in the drop links but though I would replace them, Cripes that made things worse. How can this be? my thoughts are with a failed or failing sphere but could not detect one. Back on the hoist remove front wheels with no load on arms, set the front suspension in the ride plane by hand and support. Checked n/s and o/s top ball joints under compression and found some slight movement, checked both lower pivot arm bushes, n/s had some slight movement on n/s. not showing in mot procedure. Am now in the process of replacing the parts, waiting for the top ball joints.   More on this when parts and job are completed[hopefully]. |

||

|

|

|||

321dave

|

|

||

Member No: #614

Location: Dublin |

Hi Speedfx, I'm hopefully fitting all new parts to the front suspension of the C6 next weekend. This should solve alot of well known issues with the worn suspension parts. I have pretty much new everything to go in, only bit I'm not replacing is top part of the suspension, but I do have the bushes for that part. Any tips? Did your hub need a hub puller to separate from the from drive shafts? Kind regards 321dave |

||

|

|

|

||

gmerry

|

|

||

Member No: #21

Location: Scotland |

Hi 321Dave, no need for a hub puller. Once the nut is removed, the driveshaft will just push out of the splines by hand. The tricky part is loosening and later tightening the centre nuts. Make sure they are properly torqued. Speedfix, re your photo showing the sleeve. You do realise that the FRIP joint has SKF geometry? Regards G |

||

|

|

|

||

speedfix

|

|

||

Member No: #1043

Location: south west |

"the driveshaft will just push out of the splines by hand." Why do you need to push the shaft out of the hub? |

||

|

|

|

||

speedfix

|

|

||

Member No: #1043

Location: south west |

You do realise that the FRIP joint has SKF geometry? Not when the sleeve has worn concave ho hum. |

||

|

|

|

||

321dave

|

|

||

Member No: #614

Location: Dublin |

speedfix wrote ... "the driveshaft will just push out of the splines by hand." Why do you need to push the shaft out of the hub? Hi G, many thanks for that tip! I was aware I need a 35mm socket, and I also tried a few weeks back one evening to undo the hub nuts, I bend a 1/2 breaker bar, and not a thing moved, so went and bought a 3/4 socket set for the rematch. Speedfix, I'm putting in all new hubs on the front as part of the rebuild! Looking forward to feeling the difference! I think one of the front bearings is on the way out at the moment! 117,000 miles young so far! Bye the way. Just in case I'm doing something else wrong, wouldn't be the first time. Is it lefty losey, righty tightie for the hub nut to come off? Many thanks guys I'll post pictures if all goes well. Kind regards 321dave |

||

|

|

|

||

speedfix

|

|

||

Member No: #1043

Location: south west |

321dave, yes "it lefty losey, righty tightie for the hub nut to come off" You have the correct 3/4" socket and matching breaker bar. How did you set the car up to undo the nuts? Go steady with the set bolt holding the wheel travel sensor to the lower arm as mine at 5 years old was rusted in and snapped, had to drill and tap a new thread. No need to tell you how to replace frip joints with hub still in place as you are renewing the hub bearings. May get time tomorrow to fit the pivot h/d bush with arm in place on car. will put up some pix. |

||

|

|

|

||

gmerry

|

|

||

Member No: #21

Location: Scotland |

Hi Speedfix, I'll have another try: the FRIP joints are SKF CARB bearings which are a special kind of spherical toroidal bearing. Its not a cylindrical roller bearing. Regards G | ||

|

|

|

||

321dave

|

|

||

Member No: #614

Location: Dublin |

speedfix wrote ... 321dave, yes "it lefty losey, righty tightie for the hub nut to come off" You have the correct 3/4" socket and matching breaker bar. How did you set the car up to undo the nuts? Go steady with the set bolt holding the wheel travel sensor to the lower arm as mine at 5 years old was rusted in and snapped, had to drill and tap a new thread. No need to tell you how to replace frip joints with hub still in place as you are renewing the hub bearings. May get time tomorrow to fit the pivot h/d bush with arm in place on car. will put up some pix. That would great, thanks very much Speedfx. I basically removed the castellated nut cover and pin, put back the wheel and put the 35mm socket through the wheel centre. But I should be fine with the 3/4 inch set now. I believe also the little arms for the height sensors can be replaced. Mine are also badly corroded now, could well believe they would break the minute they are touched. I was thinking do I need to fully drain the hydraulic suspension circuit as I'm putting in a new drivers side shock/strut while I'm at it. The old one is leaking now and creaking every time the car is opened and closed. Anyway I will take a few photos as I go about changing the old for new parts. How long should it take to remove the parts and replace them would you say? Kind regards 321dave |

||

|

|

|

||

speedfix

|

|

||

Member No: #1043

Location: south west |

Goodmorning 321dave, wow the ball joints arrived at 9.30 this mornning so thought I would fit one side before the grand children arrive. First to fit the pivot bush, went in with compression fit as it should. Somewhere on the forum it advises to ream out not good practice and should be deleted!   The lower arm can then be bolted up if doing in place remember to fit the two frip bolts in the holes with some water pump grease or the like. One the pivot is bolted up the ball joint can be removed, first remember to deal with lock tap. If done in place it is a good idea to cable tie the frip to the hub steering arm  this is the n/s fitted.  P/S regarding the removal of the hub nut, Dave after as you say putting the wheel on and useing the socket through the wheel centre also do not put the car in park if auto, chock the front wheels and have the hand brake on, if all fails the foot brake can be applied, never had a problem. Once the nuts are let go drive on hoist etc to carry out work, remember to slacken the lds tank cap. Also make sure the key is out of switch. Will put up a pix later on the fix with the hieght sensor links as children have arrived. |

||

|

|

|

||

321dave

|

|

||

Member No: #614

Location: Dublin |

Many thanks Speedfix for posting, very clear photos as well! I'm looking into the height sensor linkages issue as well now, might try and get some before the weekend arrives. Best of luck doing the other side this evening. Kind regards 321dave |

||

|

|

|

||

speedfix

|

|

||

Member No: #1043

Location: south west |

Reasembled the o/s and delt with all the front link joints giving them a new lease of life, may be of use if you can't get any. First spray inside the joints with hight pressure grease, get a pair of long nose thin mole grips clamp the socket part of the link above and below the direction of travel and squeeze together a little at a time till all the slop wear has gone. Hope your car will ride road hook sky hook and waft around in its former glory with no undue noises and a more response ride on the bumps etc after your refit. After a test run in my car no noises and the ride is so much better at speed. Will do the trim hieght after the suspension has settled and check with lexia, no need for spheres yet thank goodness.   |

||

|

|

|

||

speedfix

|

|

||

Member No: #1043

Location: south west |

"Hi Speedfix, I'll have another try: the FRIP joints are SKF CARB bearings which are a special kind of spherical toroidal bearing. Its not a cylindrical roller bearing. Regards G" Hi now the job is completed and all is fine I will make my case for not fitting greasers in the FRIP joints even though I fitted them on the 2.2hdi, total waste of time. First any movement is not exceptable, when the joint was removed it fell off the sleeve with full amount of soft grease [blackish] the rollers were still convex with the concave on the sleeve not being unform, have a good look at the pix, this allowed the joint to fall apart. No water passed through the lip seal it does its job. This brings me to the fact of replacement being a service item after say 24000 mls if needed when the slightest of movement is detected. Wheels slightly out of balance is another killer IMO for this type of suspension and joints. Kindest regards S. |

||

|

|

|

||

User Colour Key: User Colour Key:Head Administrator, Administrator, C6 owner, Technical Expert, C6 Premier Discount Club |

|