| C6owners :: Forums :: C6 Support :: The Garage |

<< Previous thread | Next thread >>

|

[%*^#@!] ball joints again |

Please Register to enjoy additional Member Benefits |

| Author | Post | ||

citrohanc6

|

|

||

Member No: #329

Location: utrecht |

gmerry wrote ... Difference between SKF Lower "Ball Joints" and after market replacements. Hi all, a lot of the so called Lower Ball Joints are in fact just deep groove ball bearings in a similar housing to the real thing. See - Click Here - as an example. I purchased one of these (curiosity) and in fact its a 6205 2RS bearing (probably bearing costs about £5) which has been modified by boring out centre to 27mm diameter. A standard 6205 bearing is 25mm. Seems as though all those 407s with worn out front suspensions have resulted in some creative re-engineering. Note that the genuine bearings are CARB bearings: these allow for some axial float and angular misalignment. They should look externally at least a little more like - Click Here - Regards G Some deeper digging on this, thank you for the link Gerry The oem part you show as an example from ebay , the genuine (see above), seems to be the old type CARB bearing: 3640 72 was replaced for part no. 3640 69 starting at orga no.10983 and the old sealing that prob. caused the ingres was replaced for 3623 26 since orga no. 11071 the old type sealing is as a matter of fact disparu from the part list. Winus |

||

|

|

|

||

gmerry

|

|

||

Member No: #21

Location: Scotland |

Here's a link to a good write-up for replacement of the lower "ball joints". For Peugeot 407 but essentially the same on a C6. - Click Here - |

||

|

|

|

||

gmerry

|

|

||

Member No: #21

Location: Scotland |

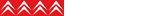

On subject of making these wretched bearings regreasable in service, I've come up with the following. -centre "cap" thickness of steel casting is only 3.2mm, ie too thin to directly screw in a grease nipple. -welding or brazing on the bearing assembly will destroy the seals due to heat. -with a very small amount of spot facing and use of a rivetbush, a 5mm depth of M6 thread plus original 3mm would create adequate thread for a M6 grease fitting. - the bearing assembly should ideally be fitted to the pivot with a bearing anerobic adhesive (Loctite) to provide a seal and stop any corrosion or galling relative movement see link for drawing of a rivnut bush. - Click Here -  Any thoughts? Regards G |

||

|

|

|

||

C6Dave

|

|

||

Member No: #1

Location: Northumberland |

Could be a plan for the more technically able G |

||

|

|

|

||

Ocellia

|

|

||

Member No: #583

Location: Bristol |

I recall the (rear?) bearings on CX weren't greaseable, but someone worked out you could drill them for a grease nipple. Pity I shed all my Citroenians! |

||

|

|

|

||

gmerry

|

|

||

Member No: #21

Location: Scotland |

Ocellia, some of the grease fitting retrofits are required for pure lubrication issues - Nissan Skylines and Imprezas - and to reduce friction/stiction in plain bearings, especially where urethane or "poly" bushes are involved. For the C6, the general feeling is a that having the ability to regrease in-situ would expel water and contaminants and hence significantly improve component life. Not familar with details on the CX, was it down to water ingress? Perhaps one to post in the Lounge Regards G |

||

|

|

|

||

citrohanc6

|

|

||

Member No: #329

Location: utrecht |

Though the bearings were considered better than the cx' rear bearings i retrofitted grease nipples in the rear needle bearings of my xm back in 1999. The main objective was iirc to lubricate once a year the bearings with 3 or 4 strikes fat to prevent them from drying out and to form a greasy surface so the Nissan impreza issue. The rear trailing arms are some sort of cast lightweight alloy so drilling 5.5mm. and let the grease nipple form its own tap did the job. Until now no problems (but the car is run down anyway) @ gerry, your proposition of a grease nipple is quite appealing. I suppose installation isn't an upside down job in situ? |

||

|

|

|

||

cruiserphil

|

|

||

Member No: #38

Location: Celbridge |

cruiserphil wrote ... Ped, Not trying to worry you but perhps it may not be at such an early stage?? See what they diagnose and keep in mind this from one of my posts on the Lower Suspensio Bearing topic. On another note, though, the local garage informed me to watch the lower bushing in the pivot carriers as they have replaced two on a C6 at 90000km. I don't know what kind of Irish roads it frequents. The bad news - the bushing is not available separately due to the way it is fitted. The whole carrier has to be replaced and the carrier costs of the order of €300. So one for members to watch although don't worry until/if it happens. I have a clunk on the front of the 06 car on braking which was there before I replaced both lower suspension bearings and after. Suspension bearings were worn anyway. I'm going to be checking tomorrow to see if I can locate it and am conscious of above. Regards, Phil C. Well I finally got to check out the clunk last weekend. Both lower wishbone rear bushes are shot. Braking and brake release provokes it. Apparently, the bush does not come as a separate piece. You replace the complete wishbone. So one to keep in mind. Will update when I get to do the job. I'll order the parts tomorrow and take it from there. Regards, Phil C. |

||

|

|

|

||

gmerry

|

|

||

Member No: #21

Location: Scotland |

Citrohanc6, I don't imagine drilling in-situ would work: the issues are preventing swarf getting into the bearings and punching over the inner side of the rivnut bush. All operations should be do-able on the bench / with a machine tool. Regards G |

||

|

|

|

||

citrohanc6

|

|

||

Member No: #329

Location: utrecht |

@ Gerry, do you think a precautionary "finger" molybdeen fat or Fluid Film or whatsoever applied from the outside will have any effect concerning the ingress of salt and water in the ball joints? |

||

|

|

|

||

gmerry

|

|

||

Member No: #21

Location: Scotland |

Citrohanc6, a little grease applied around the outside of the crevice between pivot bearing housing and the hub carrier might reduce the amount of water getting inside the bearing. I've now had one bearing replaced on the eve of the 3rd year of the warranty (failed MOT) and I replaced the other bearing even though it passed the MOT (Always do Front Suspension repairs in pairs side to side). The grease inside on the Non MOT failed bearing was very thick with corrosion products but at least not completely dry like some. Mine is the latter design, has a stainless track just visible in the attached photo. The hub pivot shaft is still steel so if it pits even a little it will destroy the lip seal in the replacement bearing and result in a short life for the repair. Regards G  |

||

|

|

|

||

gmerry

|

|

||

Member No: #21

Location: Scotland |

To replace the pivot bearings, it's probably possible to do the job without removing the brake caliper and disk but I would strongly recommend that the brake disk is removed as part of the job, it vastly improves access. The drive shaft nut must be undone so that the pivot and hub can be swung outwards. This required a 32mm socket. I use a single hex socket with a 3/4" drive and breaker bar plus about a 5 foot long bar. You also need a reaction bar that bolts onto the hub. See photo. Regards G  |

||

|

|

|

||

gmerry

|

|

||

Member No: #21

Location: Scotland |

E18 and E14 Torx (female) sockets and also an E18 torx spanner are required to remove the fasteners that hold the pivot bearing to the suspension upright. Its also very handy to have a minature puller because the inner bearing race will be left stuck on the hub. Regards G  |

||

|

|

|

||

gmerry

|

|

||

Member No: #21

Location: Scotland |

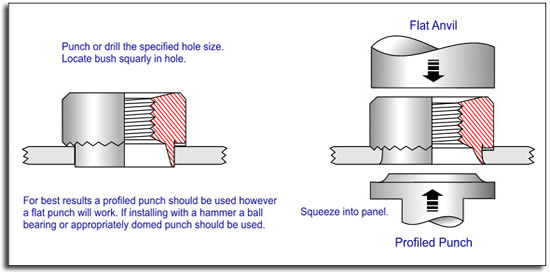

Ball Joint now fitted complete with grease fitting. So long as this in the bottom centre and facing either forwards or backwards there is plenty of room for the grease fitting and access to get the gun connected. Regards G  |

||

|

|

|

||

cruiserphil

|

|

||

Member No: #38

Location: Celbridge |

Lads, On the subject of the lower wishbones I finally got around to fitting them last weekend. As it turns out the rear bushes were completely shot. When I removed the wishbones I could pull off the rear mounting bracket as the bushing was completely detached from the wishbone. Here's a photo of new.  Here's what came out of the car.  And here's the old apart.   The wishbones are not too difficult to change. The left hand driveshaft has to be removed to allow the wishbone centre bolt to be removed, but in the case of the right hand, you have to remove the driveshaft from the hub but you can then move it to one side to get clearance to remove the bolt. There's no clunking from the front anymore. So one to watch if you're balljoints are OK! But if anyone can advise: After fitting the wishbones I followed the instruction to reprogramme the suspension heights. I did as required but the right hand front comes up with "incomplete" following an overall "programming failed" result. The other 3 are complete. There is now a permanent fault advising "programming incomplete." When I drive, I get regular Suspension Fault alerts and the front suspension feels stiff. There is no fault logged for the wheel height sensor for front right hand, but I feel this sensor may be the problem as the other 3 programmed at the same tme. I feel I need to replace it. I am going to try the reprogramme again tonight and will advise of any change. Any views? Regards, Phil C. |

||

|

|

|

||

User Colour Key: User Colour Key:Head Administrator, Administrator, C6 owner, Technical Expert, C6 Premier Discount Club |

|