| C6owners :: Forums :: C6 Support :: The Garage |

<< Previous thread | Next thread >>

|

Bottom ball joint mod. |

Please Register to enjoy additional Member Benefits |

| Author | Post | ||

speedfix

|

|

||

Member No: #1043

Location: south west |

Used two post hoist, position of arms. Tried to put up a pic of the ball joint mod but can only put up one I hope! No luck with the single pic, I will have to read up how to do a pic posting when time permits. Regarding the bottom ball joints I drilled and fitted grease nipples took longer to get the wheels off and sort out the corrosion than to do the greasers. Just wish i could put the pictures up. |

||

|

|

|||

C6Dave

|

|

||

Member No: #1

Location: Northumberland |

Please Read: How do I attach an image to a forum post in the help file you can access by clicking the  button at the top and bottom of the page button at the top and bottom of the pageBTW gmerry has already posted on how to add a grease nipple to a ball joint: - Click Here - and here: - Click Here - There is also a thread with updated part numbers here: - Click Here - |

||

|

|

|

||

speedfix

|

|

||

Member No: #1043

Location: south west |

Thanks I will have a read, the way I have fitted the grease nipples is an old way without all the tapping and threading in of the nipple. Can be done in minutes once the wheels are off,the joints do not have to be removed, can be done in place but only with good joints. The old grease was somewhat dirty once the grease gun was applied. There is nothing to stop the water [salt] getting inside the joint so greasing IMO is a must to expell foreign dirt. |

||

|

|

|

||

gmerry

|

|

||

Member No: #21

Location: Scotland |

Hi Speedfix, I avoided doing any kind of "bodge" on the car as simply drilling a hole and fitting a grease nipple will fill the joint with swarf. Regards G |

||

|

|

|

||

speedfix

|

|

||

Member No: #1043

Location: south west |

No bodge drilled up from under with the joint in place. Impossible for any swarf to get inside useing my method. Much time and expence saved don't you think |

||

|

|

|

||

gmerry

|

|

||

Member No: #21

Location: Scotland |

Hi Speedfix, any chance of enlightening the forum as to details of "your method". Thanks G |

||

|

|

|

||

speedfix

|

|

||

Member No: #1043

Location: south west |

First picture of hole drilled. More to follow! |

||

|

|

|

||

C6Dave

|

|

||

Member No: #1

Location: Northumberland |

speedfix wrote ... No bodge drilled up from under with the joint in place. Impossible for any swarf to get inside useing my method. 'Impossible' is the wrong word, improbable maybe, but my previous mechanical engineering experience tells me that drilling any assembled item in situ can allow containments to enter where you don't want them. |

||

|

|

|

||

speedfix

|

|

||

Member No: #1043

Location: south west |

No swarf will not go up hill etc etc with magnetics in place. No tapping or threads needed. Engineering experience from days gone by, yes is needed to do this quick job but many can do this simple job and have a car that transforms its self. Look at the old grease and what transformation of the road noise is now so quiet and I don't mean clonks and rumbles from a worn out joint but the road noise transmitted. Have not finished for the long term as am looking into a better grease like a sort of traction type. Nextpic will be the clever nipple.  |

||

|

|

|

||

speedfix

|

|

||

Member No: #1043

Location: south west |

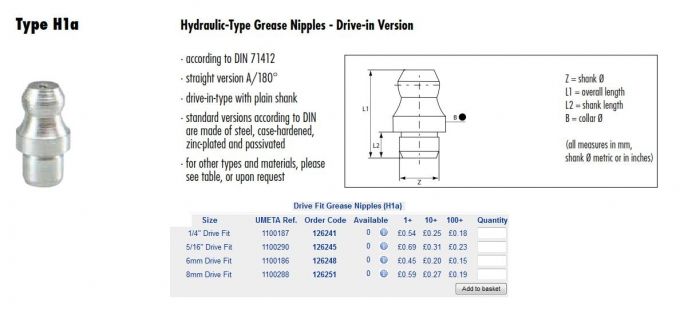

And now for the simple interference nipple, this use is for engineering experience or for those aecepting that it is impossible to get swarf in the joint, not like from tapping threads etc for the threaded type nipple! |

||

|

|

|

||

Tjensen

|

|

||

Member No: #954

Location: Bergen |

Looks elegant ! Can such a modification be ordered at a standard garage ? | ||

|

|

|

||

Gobxoy

|

|

||

Member No: #786

Location: Essex |

Now we have two options Gmerry's is the more acceted method, on which ............... Speedfix's is an alternative, if you are carfull to make sure that no debris is introduced(guess that rules out most garages) grease the drill usually helps to keep the swarf attached to the drill. You can get "drive grease nipples" with barbs on (USA)  Or these below - Click Here - data sheet - Click Here -  |

||

|

|

|

||

gmerry

|

|

||

Member No: #21

Location: Scotland |

Tjensen, to get new ball joints modified to incorporate a grease fitting, any machine shop could do this job. Then its just a standard garage job to fit. The "machining" part of the mod is spot facing the ball joint to get a flat surface, milling a tight tolerance hole (milling minimises the swarf going into the joint), cleaning out the spot of grease on the inside which will hold the swarf, degreasing, gluing / riveting in the rivnut bush (use a ball bearing to set the rivnut bush). Note there is another critical mod. The injected grease needs to have a controlled exit route - otherwise the joint will be forced apart by grease pressure. With the drive in fitting, it will be pot luck using a hand drill whether one ever get the correct interference: there's a high chance that the grease pressure will cause the fitting to be ejected. This is on top of the issue of drilling swarf getting into the joint. Regards G |

||

|

|

|

||

speedfix

|

|

||

Member No: #1043

Location: south west |

"Note there is another critical mod. The injected grease needs to have a controlled exit route - otherwise the joint will be forced apart by grease pressure. With the drive in fitting, it will be pot luck using a hand drill whether one ever get the correct interference: there's a high chance that the grease pressure will cause the fitting to be ejected. This is on top of the issue of drilling swarf getting into the joint." First may I suggest that you look at the pic of the nipple. There is no sealing ball in this type, no pressure can be held. Why have I choose this type why indeed so I can see over a service distance with a piece small gauge wire inserted to see if the ingress of water is pressent over time etc. I put it to you that drilling up with the joint in place on car with no grease on the drill bit with a magnitized area you will have no swarf ingress. If a tap was used I would use some grease however but could not garantee if swarf had entered. As for your method of washing the internals to get the milled swarf out, it will never happen as the debri will go past the rollers and collect in the top of the bearings with failings at a later date. As for the clearance being pot luck I suggest you look at the worn and new 308 Peugeot bottom ball joints on the Forum look close at the hub shamfered stub while there you could maybe tell them about this mot that takes no less than 1/2 hour once the car is up on a hoist with wheels removed. Sorry to take your thunder but this is the way forward IMO.  |

||

|

|

|

||

Gobxoy

|

|

||

Member No: #786

Location: Essex |

Boys Boys Boys, both are good. The Speedfix method as it's not sealed then pehaps it would be a good idea to put a cap over the nipple, as it would be dead easy to introduce dirt through the hole? |

||

|

|

|

||

Go to page >>

|

|

User Colour Key: User Colour Key:Head Administrator, Administrator, C6 owner, Technical Expert, C6 Premier Discount Club |

|