| C6owners :: Forums :: C6 Support :: Super Sticky |

<< Previous thread | Next thread >>

|

Steering bottom swivel (FRIP) replacement & lube system flush |

Please Register to enjoy additional Member Benefits |

| Author | Post | ||

e3steve

|

|

||

Member No: #1163

Location: Warsash, Hants & Palma de Mallorca, Spain |

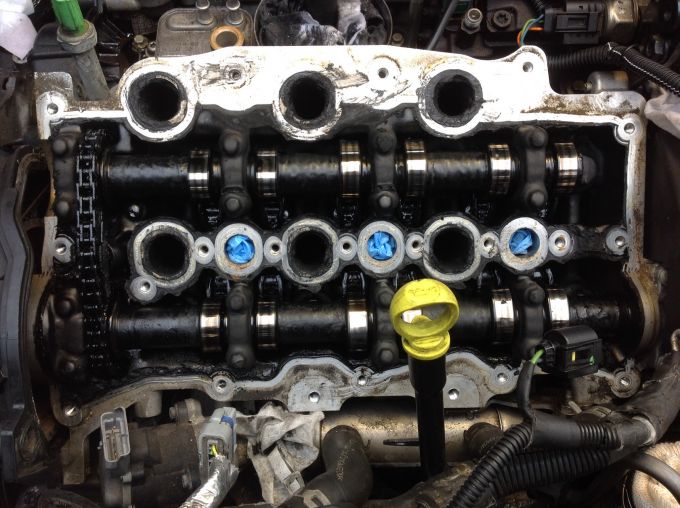

Not a difficult task, really, but you do need to be 'tooled up'. I replaced mine on Saturday, along with carrying out my first oil & filter change on a C6, allowing the hot oil to drain completely whilst the suspension surgery was undertaken -- I replenished the lubricant with 5 litres of cheapish diesel-specific, detergent, semi-synthetic 15W/40 and about half a litre of bog-standard ATF; this should encourage a bit of 'flushing' action to, hopefully, break down this lot: The above image was captured whilst replacing its stubborn glowplugs a while ago. As you will observe, the heads of the camshaft caps' screws are barely recognisable as hex-heads! I shall be changing the oil & filter again in a couple of weeks, running a similar mix of lube for another flush. For the FRIP job I needed:

At this point I had to carefully cut into the bearing journal that was stuck fast on the hub spigot. A shallow-angled cut over about 25mm of the journals' circumferences took a couple of minutes each side, then the journals just came off easily with two flat screwdriver blades. I cleaned up the spigot again with the wire brush and smeared it with electrical silicon grease (RS part 494-124). I also smeared the FRIP bearings fully with same. I've also performed a variation on speedfix's theme; easy enough to drill a tap and fit an M6 grease nipple into each before fitting:  Just need to get myself a grease gun now! |

||

|

|

|||

C6Dave

|

|

||

Member No: #1

Location: Northumberland |

After going to all that trouble and given that the issue seems to be water contamination due to a failed seal, I recommend that you buy some 'Quicksilver 2-4-C Marine Grade Grease' to lubricate the joints. It's water resistant and has Teflon as well and if it's good enough for boat trailers, engine shafts etc. that go under sea water, it should resist UK winter roads  Not the cheapest around but I've used it on the Traction for over a year now. |

||

|

|

|

||

verycleverman

|

|

||

Member No: #65

Location: Northumberland |

e3steve wrote ... I cleaned up the spigot again with the wire brush and smeared it with electrical silicon grease (RS part 494-124). I also smeared the FRIP bearings fully with same. I would caution against using silicone grease anywhere near mechanical components. It has zero load bearing properties and can seriously affect the integrity of some 'rubber' seals. Many modern seals are manufactured from a silicone compound and silicone grease can break down the compound. I cannot think of a single valid reason for using it on a bearing. It's only approved use is for protecting electrical connections - notably battery terminals. Pete. |

||

|

|

|

||

gmerry

|

|

||

Member No: #21

Location: Scotland |

E3Steve, just a warning with the grease nipples: after injecting some grease, you will probably find some has deposited itself on the brake disk. Obviously this must be thoroughly cleaned. Putting a small needle hole(s) on the side of the bearing boot way from the disk minimises the problem. Once the FRIP joint is installed, its too late to prick the seal as it becomes shielded by the suspension arm. Regards G |

||

|

|

|

||

e3steve

|

|

||

Member No: #1163

Location: Warsash, Hants & Palma de Mallorca, Spain |

verycleverman wrote ... Thanks Pete. 'Twas just a smear to offset any corrosion for a while, not for lubrication purposes. The FRIP bearing is pre-greased and sealed but that only protects and lubes it internally, of course.e3steve wrote ... I cleaned up the spigot again with the wire brush and smeared it with electrical silicon grease (RS part 494-124). I also smeared the FRIP bearings fully with same. I would caution against using silicone grease anywhere near mechanical components. It has zero load bearing properties and can seriously affect the integrity of some 'rubber' seals. Many modern seals are manufactured from a silicone compound and silicone grease can break down the compound. I cannot think of a single valid reason for using it on a bearing. It's only approved use is for protecting electrical connections - notably battery terminals. Pete. |

||

|

|

|

||

User Colour Key: User Colour Key:Head Administrator, Administrator, C6 owner, Technical Expert, C6 Premier Discount Club |

|