| C6owners :: Forums :: C6 Support :: The Garage |

<< Previous thread | Next thread >>

|

LDS leak above the fuel tank. |

Please Register to enjoy additional Member Benefits |

| Author | Post | ||

AivarVal

|

|

||

Member No: #1956

Location: west-viru ESTONIA |

Hi all. My beloved c6 started leaking LDS again.It drips down the fuel tank.Is there only pressure tube or backing tube is located also there.Some thouts and pictures please. Today i lfted the car and looked closely.yes the tube is rotten above the fueltank corner.the tube is very long.what jou think how i must repair that, or only new tube helps solve this problem.i cant belive im first with ho this is happened. sorry my bad english. |

||

|

|

|||

AivarVal

|

|

||

Member No: #1956

Location: west-viru ESTONIA |

Hi all.im sad, no replies so far.i got new idea to put new piece of tube around the fueltank not over it .and depressurise only the back end of the car.what you think, its duable or not.im not sure about bleeding nessesserity in that case also. |

||

|

|

|

||

gmerry

|

|

||

Member No: #21

Location: Scotland |

Hi Aivar, sorry to hear you have a hydraulic leak. Is it on the pressurised pipe to the rear suspension (is there a non pressurised return?) Do you have access to a drawing showing the arrangement of the parts? My initial thinking is that it will be very difficult to splice together a new tube into old tube so compare any "repair" solution with replacing the corroded pipe back to the original joint. regards |

||

|

|

|

||

AivarVal

|

|

||

Member No: #1956

Location: west-viru ESTONIA |

Yes there is two pipes pressure pipe is steel one and return is made of plastic. Steel tube is rotted only in one small section .im planing to cut the rotten section out and with hydraulic connectors put the new short piece of tube in. The original tube is wery long and has lots of corners, so. replace all the tube is very big job (removing the fueltank ,lots of plastics etc) . i hope this fix does the job. |

||

|

|

|

||

gmerry

|

|

||

Member No: #21

Location: Scotland |

Hi Aivar, yes I agree from what I can see that replacement of the entire tube section looks like a very long and complicated job. Obviously you need to find straight runs for the hydraulic connector. Getting a clean, corrosion free external surface will be key if you are to avoid a fatal contamination of the hydraulics. What brand of connector are you going to use (compression double ferrule?). At the component ends of the steel tubes, Citroen use a proprietary sealing system with a formed tubing flare, a seal and a parallel thread. In 10mm steel this would be virtually impossible to reproduce but I would like to be proven wrong. I have an example sitting on my workbench to remind me of how difficult this tubing connection is. Let us know your detailed plan. |

||

|

|

|

||

AivarVal

|

|

||

Member No: #1956

Location: west-viru ESTONIA |

OK In friday i go to the local garage.i let you know how it went.Plan its to use copper tube piece between connectors.i hope copper tube is not the problem. |

||

|

|

|

||

travlician

|

|

||

Member No: #350

Location: Paradera |

I have replaced some steel LHM tubing on my CX once and it bursted after a few months. Since C6 is heavier with higher pressures this is more risk but being rear where pressures are lower it might work. Seek copper tubing for R410 airconditioning systems, this has a thicker wall due to higher working pressures. | ||

|

|

|

||

gmerry

|

|

||

Member No: #21

Location: Scotland |

Hi, splicing in to steel hydraulic line is not a simple process so I wish you luck. IMHO, the tricky aspect is getting a strong leak free connection on to the OLD section of steel line, never mind the connection on to the new spliced in portion (copper, steel, stainless etc). The preparation of the old section is key, as is cleanliness. It might be possible to ease the job by only having one new/old connection by purchasing a new line (to the component and then cutting this new section at the point where you wish to make the joint on to the old. Advantage, only one connection to be made and you may have a better option in terms of location of the spliced joint. Again, how you go about cutting the tubing is key: any kind of saw will produce swarf contamination. Another option is a very good quality tube cutter if you have enough clearance to use it. regards |

||

|

|

|

||

gmerry

|

|

||

Member No: #21

Location: Scotland |

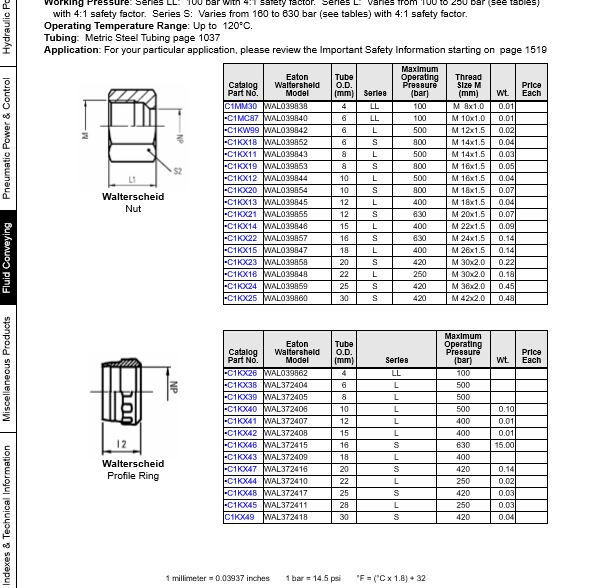

Maybe an Eaton 7000 series flareless fitting (theoretically available in metric sizes see extract) might be used to make the splice connection. regards

|

||

|

|

|

||

AivarVal

|

|

||

Member No: #1956

Location: west-viru ESTONIA |

So today i sorted this out, with two connectors and 1 metre of copper tube.It went nicely but when we cut the old pipe then, there was a wire inside the steel tube.Maybe somebody knows what purpose the wire has there. Strange enyway. |

||

|

|

|

||

gmerry

|

|

||

Member No: #21

Location: Scotland |

Great news. Any Photos? What kind of connectors, manufacturer and model number. What spec for the copper pipe. regards |

||

|

|

|

||

Hattershaun

|

|

||

Member No: #320

Location: Bedfordshire, UK |

I believe the wire inside the pipe acts as a damper to slow the flow rate of fluid and act as a cushion, to avoid sudden peaks of high pressure fluid acting on joints and other hydraulic components. | ||

|

|

|

||

gmerry

|

|

||

Member No: #21

Location: Scotland |

Shaun, do you mean some kind of "water hammer" dissipater? regards |

||

|

|

|

||

User Colour Key: User Colour Key:Head Administrator, Administrator, C6 owner, Technical Expert, C6 Premier Discount Club |

|