| C6owners :: Forums :: C6 Support :: Super Sticky |

<< Previous thread | Next thread >>

|

Looking after your tyre pressure sensors |

Please Register to enjoy additional Member Benefits |

| Author | Post | ||

C6Dave

|

|

||

Member No: #1

Location: Northumberland |

Well I left FCS at Rockingham in Northampton today at 2.15 pm today (Sunday) for a 200 mile journey and had gone 2 miles when the Service light came on and a low tyre pressure warning to go with it on the nearside rear Stopped at the first garage I came to, to check the pressure and....................... Yep, the plastic dust cap wouldn't come off (a common problem) b****r So, trying to force off with pliers is highly likely to shear the valve stem and I didn't fancy a 200 mile drive on the 55mph restricted spare so what to do? Cut the dust cap off to check the pressure and rule out a faulty sender unit Guess what though, I had no knife, nor did the garage so as the tyre looked OK decided to carry on to the next garage to see if they could help At the 4th garage after 40 miles (no one had a knife or sold tools) I had a bit of luck, a Gilbarco service engineer was fixing a pump and lent me a knife so I was able to cut the cap off and add some air. Yes the pressure was low and the system reset OK Just confirms though that you should check the caps regularly to ensure they don't seize on and keep them lubricated with something non setting, oh and carry a knife just in case they still decide to lock themselves on, never try and get them off with pliers

|

||

|

|||

gmerry

|

|

||

Member No: #21

Location: Scotland |

A wipe with Bilt Hamber Ferrosol does the trick for me. When it comes time to change the tryes, what is the deal with the tyre sensors or removal, refitting, new valve core? Regards G |

||

|

|

|

||

tonyrome

|

|

||

Member No: #15

|

I check my tyre pressures regularly and always before a major journey. Even if the pressure sensors prevent running with low pressures, you always need to adjust between 2.4 bar and 2.6 bar for normal or high speed/laden. As a result of regular checks, I've never had any problem with the caps or sensors. | ||

|

|

|

||

C6Dave

|

|

||

Member No: #1

Location: Northumberland |

tonyrome wrote ... I check my tyre pressures regularly and always before a major journey. Even if the pressure sensors prevent running with low pressures, you always need to adjust between 2.4 bar and 2.6 bar for normal or high speed/laden. As a result of regular checks, I've never had any problem with the caps or sensors. My own fault I know, I should have checked before we left, but had to much to do and it got overlooked. Lesson learned. @gmerry, as far as I remember, the original sensors had a fixed core, so you had to change the whole sensor, the newer ones have been modified with a replaceable core though. |

||

|

|

|

||

Dave Mc

|

|

||

Member No: #64

Location: Weston-super-Mare |

Top Tip: Every time you wash your C6 when you get to each wheel just loosen each cap and tighten it again. It has become a habit which I hope will prevent problems in the future. PS I never use a car wash - too many scratches!! |

||

|

|

|

||

gmerry

|

|

||

Member No: #21

Location: Scotland |

Dave, your reply has me worried. Normally when changing tyres, the fitter will automatically discard the old rubber valve fittings and cores. If you say the "older" style have a non replaceable core, does that mean new transmitters are required for each tyre change? Also, how will I tell if I have the old or the new style transmitters with replaceable cores. Regards G |

||

|

|

|

||

michaelb

|

|

||

Member No: #14

Location: London |

Following the replacement of two tyres recently I had a deflation a few days later. It turned out to be the valve insert (the actual valve itself) not screwed home properly. With traditional valves the tyre-fitter normally pulls out the whole valve, usually with a pliers, and discards it. This obviously deflates the old tyre to allow removal. As they can't do this with the sensor type valves they have to deflate the tyre by unscrewing the insert and replacing it (hopefully screwed in sufficiently tightly). I never understood why traditional valves are discarded in this manner. I just assumed it was a combination of it being the quickest way to deflate the tyre and an opportunity to force-sell you something which has a good mark-up. To come back to your point I don't see that new transmitters are needed for each tyre change, just the fitters have to be careful not to attack them with a pair of pliers. C6Dave wrote ... Stopped at the first garage I came to, to check the pressure and....................... I carry a little compressor for just such emergencies. However, when I recently had a similar deflation I couldn't get my Michelin compressor to mate with the sensor valves on my Michelin tyre. The compressor had worked fine on my previous car's wheels. C6Dave wrote ... Well I left FCS at Rockingham At the 4th garage after 40 miles (no one had a knife or sold tools) Security, innit? You could 'ave been a terrorist! |

||

|

|

|

||

C6Dave

|

|

||

Member No: #1

Location: Northumberland |

Yes I used to have one of those mini compressors as well but they tended to loose more air from the connector than they pumped in so binned it! | ||

|

|

|

||

C6Dave

|

|

||

Member No: #1

Location: Northumberland |

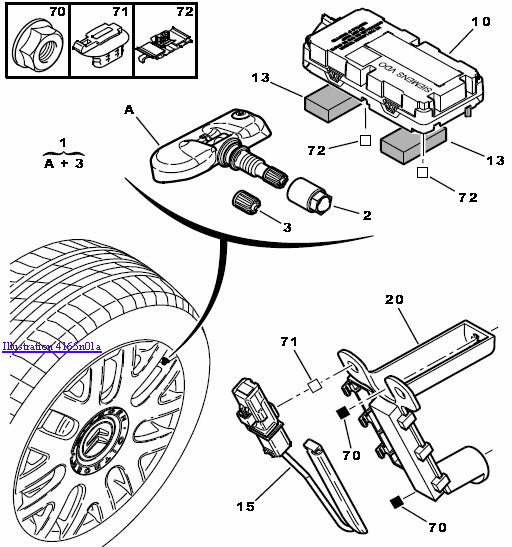

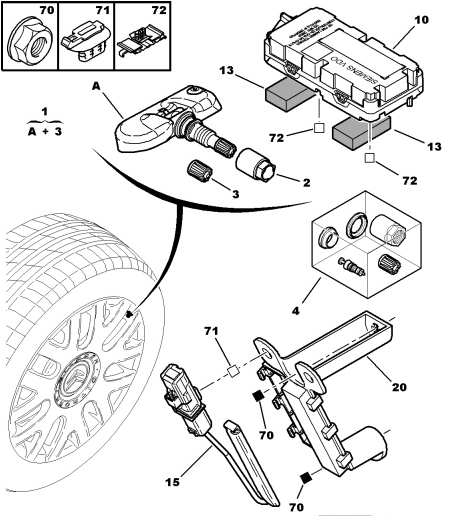

gmerry wrote ... Dave, your reply has me worried. Normally when changing tyres, the fitter will automatically discard the old rubber valve fittings and cores. If you say the "older" style have a non replaceable core, does that mean new transmitters are required for each tyre change? Also, how will I tell if I have the old or the new style transmitters with replaceable cores. Regards G To show the differences I have found: Pre RPO 1080  Since RPO 1081  As you can see, you can get a repair kit - 5412.05 - for the later ones with a replacement valve core which are £6.24 retail each. Visually from the outside, I don't know how you tell the difference! |

||

|

|

|

||

tonyrome

|

|

||

Member No: #15

|

Out of interest, are the C4 tyre pressure sensors the same as those for the C6? | ||

|

|

|

||

C6Dave

|

|

||

Member No: #1

Location: Northumberland |

Whilst they look the same, the part number is slightly different 5430 H1 for the C4 VTS 5430 95 for the C6 I have no idea what the differences are though. |

||

|

|

|

||

gmerry

|

|

||

Member No: #21

Location: Scotland |

Update on Tyre Pressure Monitors. Well for last two very salty winters, I have kept the tyre valves lubricated with a hint of Ferrosol, so no problems with the caps corroding on solid. My last two Michelins are fully worn out (and cracked) so time for a fresh set of tyres. Also I kerbed one of the wheels so needs a cosmetic repair and refinish. Heeding the Citroen Mechanic's guidance that the valve stems (service repair kit) should be changed with every tyre change, even though the transmitter battery life is about 7 years, I had the cunning plan to get tyres removed, remove the transmitters, get wheels refinished and then replace transmitters with fresh new alloy valve stems... or so I thought. On removal of the tyres, the valve stems were found to be massively corroded to the nut. One could be unscrewed (but needed a lot of effort and the transmitter was cracked in the process). The other valve stem had to be drilled out because the corrosion was so bad. Now I know some folk have just replaced their tyres without touching the transmitters at all (yes I did this for the first two Michelin replacements) but the fact that these new tyres and valves will probably be in service in 2-3 years time with all that additional corrosion kind of told me that the "leave well enough alone" approach was not a reliable proposition. As an aside, I see that for the 2008 onwards Citroen C4, the design of the Transmitter changed to a pretty conventional looking rubber/brass valve stem that the transmitter attached to (plus they are only 1/2 the price of the original C4/C6 VDO type). So an ideal "upgrade" might be to swap out the ECU for a latter C4 type and use the later rubber/brass pressure transmitters. So morale of the story is, don't rely on just changing the service kit because the valve stems/nuts will probably be severly corroded. Do think very hard about just running the valves forever and not changing them at a tyre change. Probably count on replacing the entire transmitters. Regards G |

||

|

|

|

||

C6Dave

|

|

||

Member No: #1

Location: Northumberland |

You can change the valve stems and retain the original transmitters G I have seen them advertised somewhere.......... EDIT: here on eBay: - Click Here - |

||

|

|

|

||

gmerry

|

|

||

Member No: #21

Location: Scotland |

Dave I have the spare replacement valve stems and the intention was to carefully remove the stems, separate from transmitter and replace with new stems. Problem is that the transmitter cannot be separated from the corroded stem without destroying the transmitter, because the end of the stem is anchored within a plastic cavity which is part of the transmitter. When everything is nice and new, replacement valve stems will work OK. As soon as there is corrosion between the stem and the nut, then the replaceability of the valve stem becomes a bit of a red herring. Thats why my local very good tyre shop will not touch the things! Obviously VDO/Siemens recognised they had a poor material choice / design problem. So the 2008 onwards C4 has the rubber/brass stems to avoid these issues. I'll post a photo later showing what the problems are Regards G |

||

|

|

|

||

verycleverman

|

|

||

Member No: #65

Location: Northumberland |

gmerry wrote ... So the 2008 onwards C4 has the rubber/brass stems to avoid these issues. I looked at those the other week when I was researching for a friend of mine; they appear to have a groove around the base, as though they were for steel wheels. I doubt they would be any good for the C6. Pete. |

||

|

|

|

||

Go to page >>

|

|

User Colour Key: User Colour Key:Head Administrator, Administrator, C6 owner, Technical Expert, C6 Premier Discount Club |

|