| C6owners :: Forums :: The Lounge :: The Lounge |

<< Previous thread | Next thread >>

|

Aluminium Suspension Components - Cobapress |

Please Register to enjoy additional Member Benefits |

| Author | Post | ||

gmerry

|

|

||

Member No: #21

Location: Scotland |

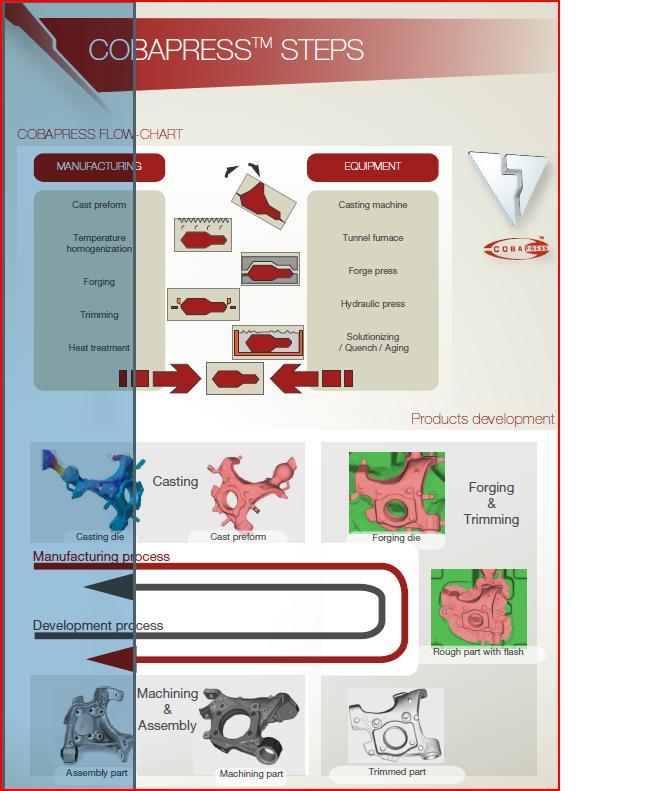

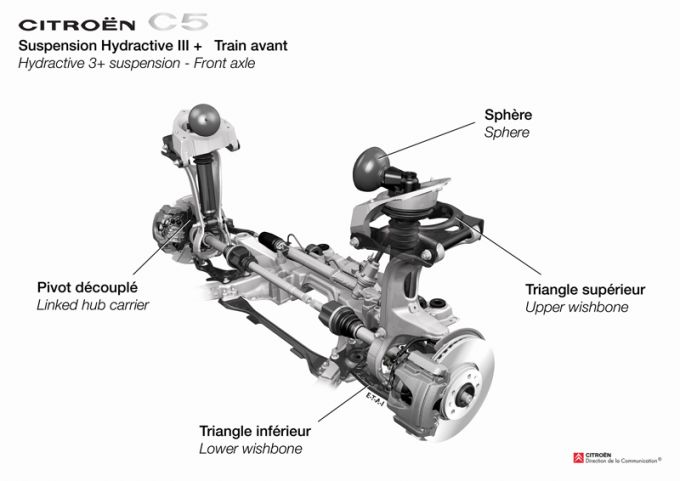

Trivia, C6 aluminium suspension components are manufacture using a process patented by Saint Jean Industries - Cobrapress. Its a Hybrid Cast/Forged/Machining process with most of the advantages of these individual technologies and little of the downsides. see attached.

|

||

|

|

|||

citrohanc6

|

|

||

Member No: #329

Location: utrecht |

Yep interesting, cobapress; new procedure. it gives ordinary light alloy the quality of titanium. Fabrication of these parts under high pressure to obtain a dense structure. Isn't it manufactured in Charleville Mezieres in Nothern France? |

||

|

|

|

||

Gobxoy

|

|

||

Member No: #786

Location: Essex |

Shame they corrode so 'orribley The top 508 looks to have more robust uprights compare to C5/6 407 etc?   |

||

|

|

|

||

citrohanc6

|

|

||

Member No: #329

Location: utrecht |

okay due to friction and strain nuts and bolts rusts, but doen't the oxidation layer on the part forms a protection as the material isn't laquered or protected in any other way (forgot the tecs) |

||

|

|

|

||

Gobxoy

|

|

||

Member No: #786

Location: Essex |

citriohanc6 wrote:- due to friction and strain nuts and bolts rusts Not sure what you mean by "due friction and strain"? Pure aluminium forms a protective oxide, which is why Alclad TM of Alcola make the stuff to protect the alloy underneath see here - Click Here - . Aluminium alloys do corrode. The first picture of my earlier post, shows this? Look at the top the spring mount the "spring tower" where it contcts the body closly enough to prevent oxidation, and again on the upright under the machined resses where the washer has stop the air getting to the alloy. Given enough time the parts will fail, but as I haven't heard of old 407 falling off the road in huge numbers due to this, I don't think it's a big concern. However it doesn't look very attractive.  I think if I ever get mine back????????? I think if I ever get mine back????????? I might just pull the wheels off and give the alloy parts a quick coat of wheel lacquer. |

||

|

|

|

||

C6Dave

|

|

||

Member No: #1

Location: Northumberland |

Give the alloy parts a coat of Ferrosol and it protects them from surface oxidisation | ||

|

|

|

||

citrohanc6

|

|

||

Member No: #329

Location: utrecht |

"The top 508 looks to have more robust uprights compare to C5/6 407 etc?" yeah a solid upper wishbone (made of steel?) with an axle in stead of a rusty bold. It sure is improved. I think the strain caused the bolt to rust. Broke my tarsal bone, so we are more or less in the same situation. Hope you'll see your car back shortly! Winus |

||

|

|

|

||

Gobxoy

|

|

||

Member No: #786

Location: Essex |

citrohanc6 yep thats why I posted the pics 508 GT does look more robust. gold star to you sir. sorry to read you broke your foot. I hope to see my car back sooooon tooooooooooooooo. |

||

|

|

|

||

User Colour Key: User Colour Key:Head Administrator, Administrator, C6 owner, Technical Expert, C6 Premier Discount Club |

|